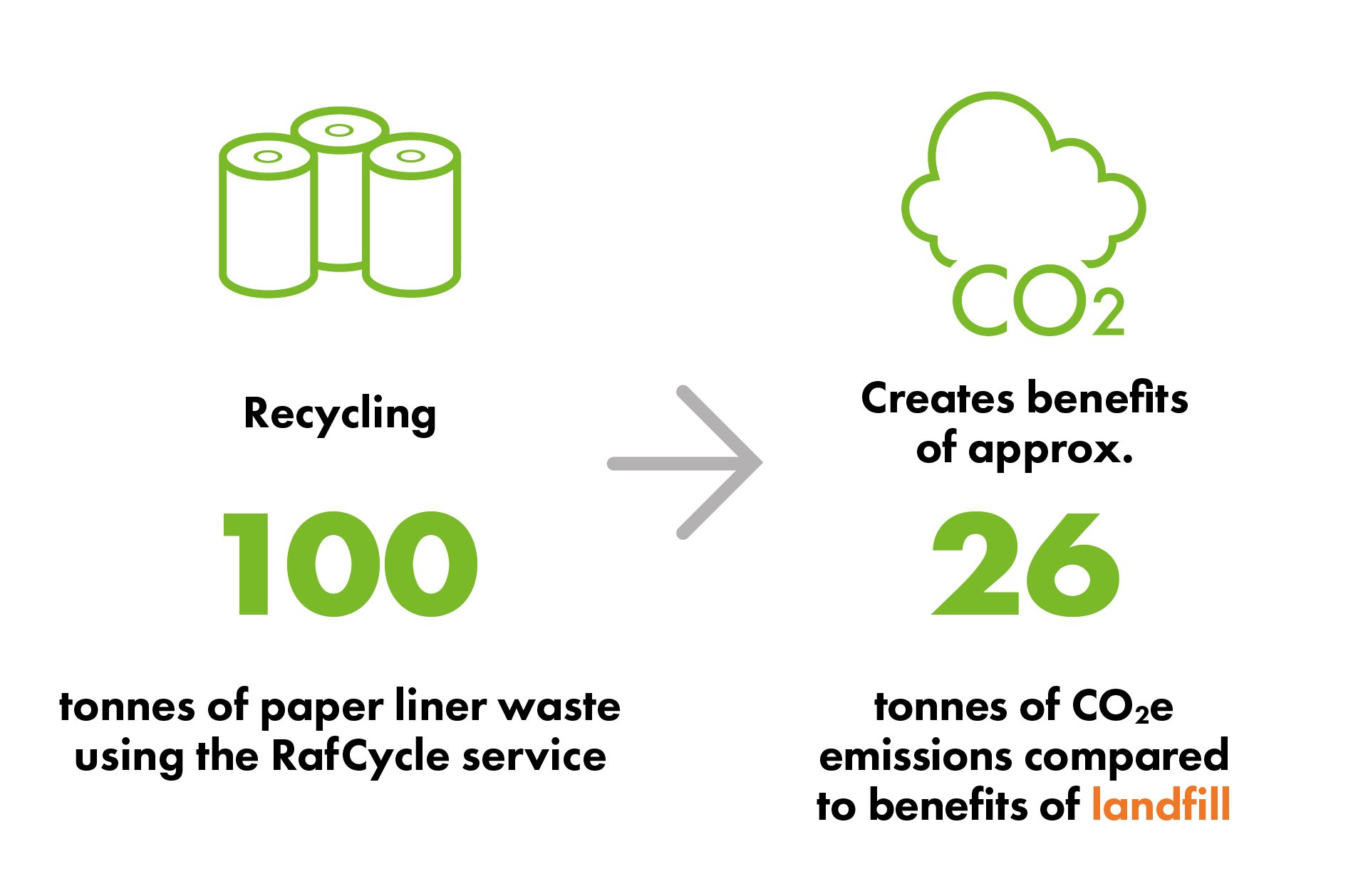

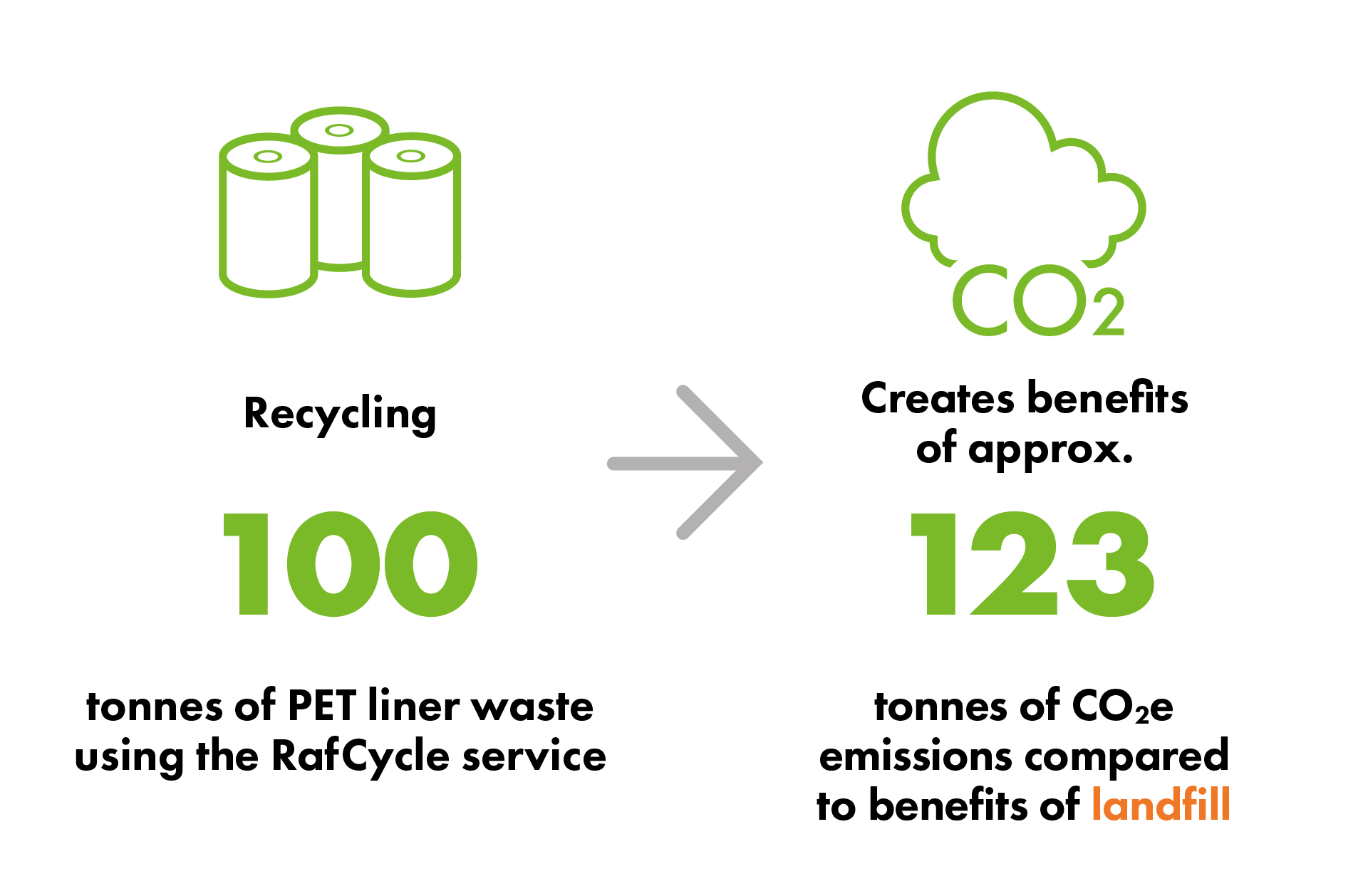

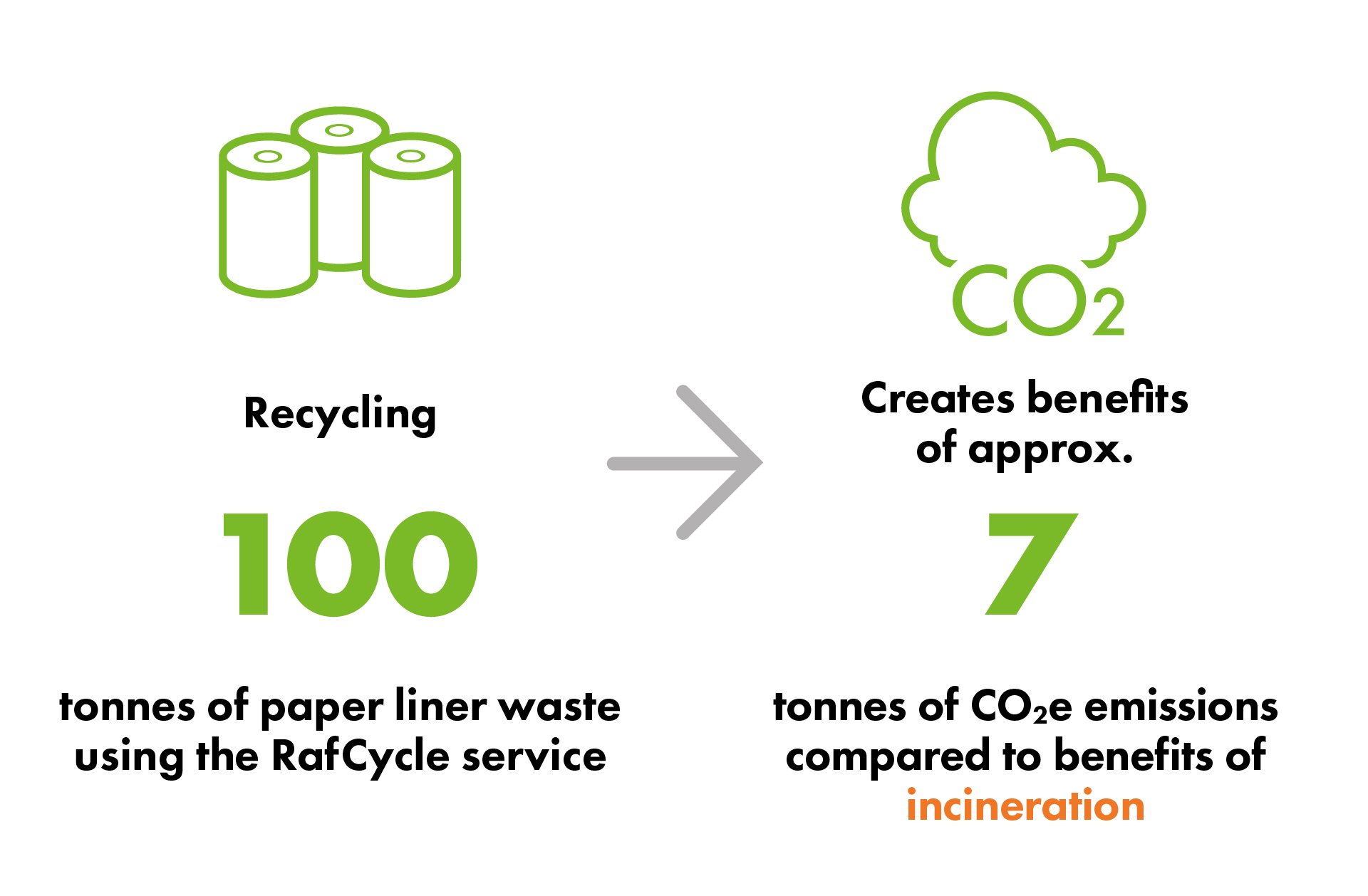

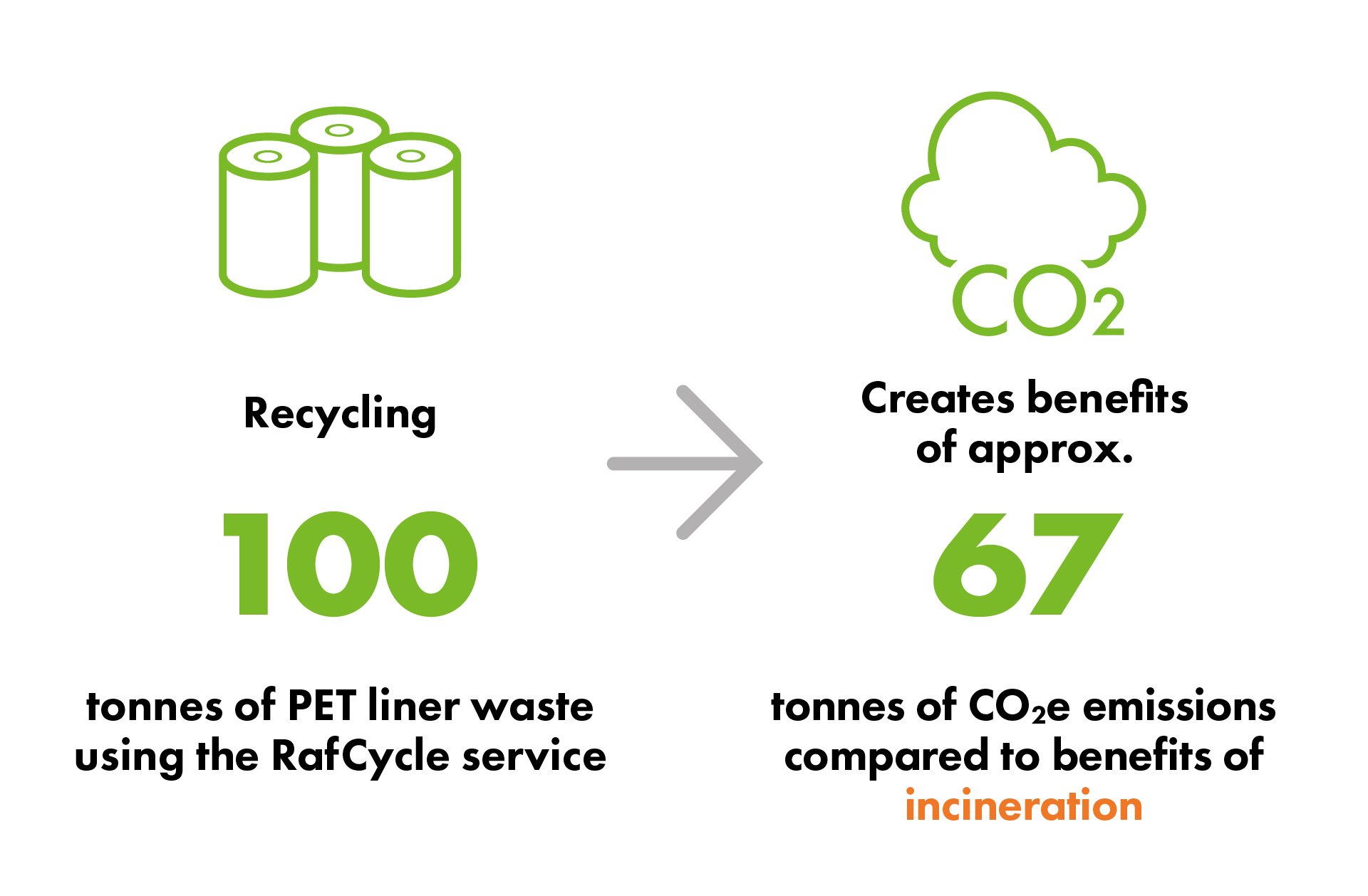

The simple act of recycling release liner can support your climate targets. The global waste issue is real, with the linear use of materials contributing to climate change. Brands and converters are facing pressure from tightening sustainability regulations and shifting consumer preferences.

Label release liner remains an under-addressed waste stream globally, with low recycling rates worldwide. With RafCycle, your company can help foster a circular economy while meeting compliance requirements and the demands of sustainably conscious customers. Join our growing network of partners committed to advancing towards circularity alongside us.